Here are a few distinct features of firebricks and regular bricks. As the leading brick manufacturers in India, our experts have immense knowledge in firebricks and they can help you better. Call us now!

High Heat Resistance

Regular bricks are highly porous and cannot withstand temperatures above 1200 Fahrenheit. However, at Emperors Vitrified Porcelain, we do not compromise on quality. We are the most reputed brick manufacturers in India, and our bricks meet the highest quality standards.

Durability

Composition

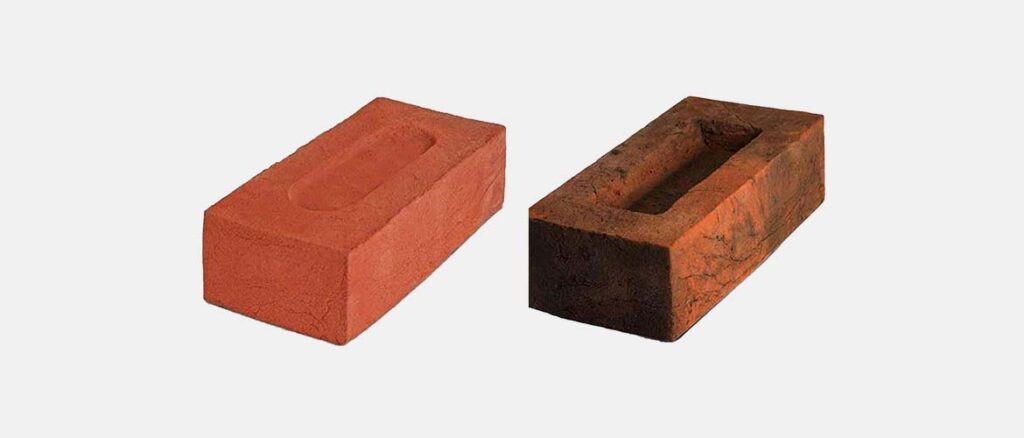

Look & Finish

Regular bricks, as we know it, is usually red in color. One of the more common shades is a reddish-brown. But, as one of the most trusted brick manufacturers in India, we realized that our clients were looking for something more. Something unique. So we decided to create more options. Our collection of regular bricks now includes tinted red bricks, Blended Mix bricks, reclaimed bricks, grey, black, and even white color regular bricks. So there is actually no dearth of option for someone looking for regular bricks.

Thermal Conductivity

Application Of Firebricks VS Regular Bricks

They do not require additional insulation, which saves on materials and labor costs. They also offer thermal insulation and acoustic insulation, which reduces energy consumption and increases building comfort. Firebricks offer superior thermal insulation and acoustic insulation, which makes them ideal for radiant cooling and radiant heating applications. They are also appropriate for buildings that are exposed to heat. Talk to an expert team from renowned brick manufacturers in India, like Emperors Vitrified Porcelain, who can offer better insights into the applications of firebricks in your project.

When To Choose Firebricks Over Regular Bricks?

It is also important to order your bricks from the No.1 brick manufacturers in India – Emperors Vitrified Porcelain brings decades of experience in manufacturing and delivering high quality construction materials, including bricks. You can even place custom orders of bricks for your building. Call us today and our team will be happy to assist you.